Md Ehsanullah, Satyam Singh, Rohit Kumar

1 Department of Civil Engineering, Madan Mohan Malaviya University of Technology Gorakhpur, Uttar Pradesh, India

2 Centre of Sustainable Technologies, Indian Institute of Science, Bengaluru-560012, India

*Author to whom correspondence should be addressed:

satyammmmut01@gmail.com (S. Singh); rkce@mmmut.ac.in (R. Kumar)

ABSTRACT

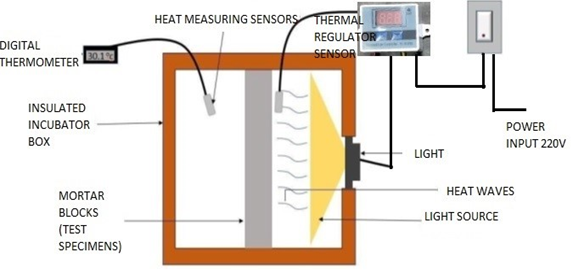

This study explores the thermal conductivity and mechanical properties of mortar compositions incorporating agricultural waste materials, specifically Rice Husk Ash (RHA) and Bagasse Ash (BA), as sustainable alternatives. Experimental results indicate a marked reduction in thermal conductivity as agro-waste content increases. Notably, Rice Husk Ash-based mortar (RH15) and Bagasse Ash-based mortar (BA15) exhibit reductions in thermal conductivity of 19°C and 17°C, respectively, when compared to traditional Portland Pozzolana Cement (PPC) mortar after four hours of exposure. In geopolymer mortars, mix 7 demonstrates superior thermal performance, with RHA and BA reducing thermal conductivity by 12°C and 14°C, respectively, compared to Fly Ash-based Geopolymer mortar (FA7). The study also evaluates the shrinkage tendencies of the mortars, revealing that higher agro-waste content mitigates shrinkage, with Bagasse Ash-based mortars showing the lowest linear shrinkage at 5% sand replacement. Mechanical strength analysis further highlights the beneficial effects of Bagasse Ash, particularly in PPC-based mortars, where strength improvements are observed at both 5% and 15% sand replacement. Among geopolymer mixes, mix 7 emerges as the optimal design in terms of both thermal and mechanical performance. These findings emphasize the potential of agricultural waste materials to enhance the sustainability and efficiency of mortar compositions, contributing to reduced environmental impact and improved construction materials.

Significance of the study:

This study highlights the potential of incorporating agricultural waste materials, such as Rice Husk Ash (RHA) and Bagasse Ash (BA), into mortar compositions. By reducing thermal conductivity, enhancing mechanical strength, and minimizing shrinkage, these agro-waste-based mortars present a sustainable and efficient alternative to conventional materials. The findings emphasize their value in promoting environmentally-friendly construction practices while enhancing thermal insulation and structural performance.

Summary of the study:

The study investigates the thermal and mechanical properties of mortar incorporating Rice Husk Ash (RHA) and Bagasse Ash (BA) as sustainable alternatives. Results show significant reductions in thermal conductivity and shrinkage, with improved mechanical strength in both conventional and geopolymer mortars. RHA and BA-based mortars demonstrated superior thermal performance, particularly at 15% sand replacement levels. The findings underscore the benefits of agro-waste in creating efficient, sustainable construction materials.