S. Ganesan, Sravanth Chandaka, Neethusri Velangi, Jayaprasad, C. Shanthi, Satyaprasad

1 Vel Tech Rangarajan Dr. Sagunthala R&D Institute of Science and Technology, Vel Nagar, Chennai-600062, Tamilnadu, India.

2 Madras Institute of Technology, Chennai, 600044, Tamilnadu, India.

3 Chennai Institute of Technology, Chennai, 600069, Tamilnadu, India.

* Author to whom correspondence should be addressed:

ksganeshme@gmail.com (S. Ganesan)

ABSTRACT

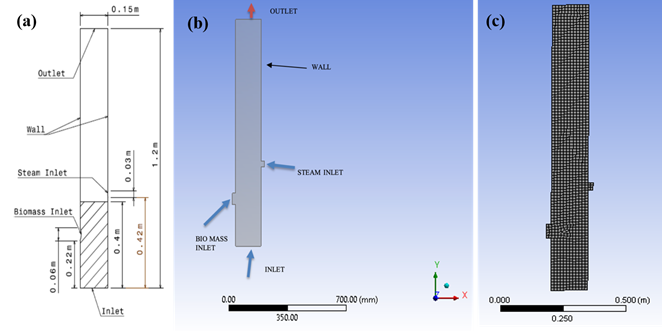

Gasification is an efficient process that converts organic and fossil fuel-based carbonaceous materials into valuable gases such as carbon monoxide, carbon dioxide, and hydrogen, which can be used as fuel. This study aims to enhance the efficiency of the gasification process by utilizing a Computational Fluid Dynamics (CFD) model to simulate a Fluidized Bed Gasifier (FBG) system. Sawdust serves as the fuel, while sand particles form the fuel bed. The model, developed using the Eulerian-Eulerian approach, explores the effects of air preheating and variations in particle size on the composition of producer gas. By analyzing particle sizes of 0.5 mm and 1 mm at preheating temperatures of 400 K and 600 K and a velocity of 1 m/s, the study reveals significant variations in gas composition. At 400 K, the mole fraction and mass fraction of fuel gases such as CO and H₂ increase for larger particle sizes, reaching peak performance for 1 mm particles. The performance of the gasifier improved by 75% at 400 K for 1 mm particles. However, when the temperature was increased to 600 K, CO was converted to CO₂, demonstrating that higher temperatures lead to increased combustion of fuel gases. This study offers valuable insights into optimizing gasification processes for enhanced energy efficiency and gas yield in fluidized bed systems.

Significance of the study:

The study provides critical insights into optimizing gasification processes in fluidized bed systems for enhanced energy efficiency and gas yield. By examining the impact of particle size and air preheating temperatures, it highlights a promising approach to improve syngas production, particularly in biomass-based gasification. These findings can significantly benefit the renewable energy sector, contributing to sustainable fuel production and more efficient utilization of carbonaceous materials.

Summary of the study:

This study investigates the performance of a Fluidized Bed Gasifier (FBG) using sawdust as fuel through Computational Fluid Dynamics (CFD) modeling. The analysis explores the effects of particle size (0.5 mm and 1 mm) and air preheating temperatures (400 K and 600 K) on the gas composition. Results show that larger particles (1 mm) at 400 K lead to improved gas production, especially of CO and H₂, with the gasifier’s performance increasing by 75%. However, at 600 K, higher combustion levels reduce fuel gas yield.