Saipan H. Tamboli, D. M. Sirsat, S. T. Sankapal, S. I. Bagwan, S. S. Tamboli, G. R. Patil, Sikandar H. Tamboli

1 Department of Chemistry, M. H. Shinde Mahavidyalaya, Tisangi affiliated to Shivaji University, Kolhapur, MS, (416206) India.

2 Department of Chemistry, Nya. Tatyasaheb Athalye Arts, Ved. S. R. Sapre Commerce & Vid. Dadasaheb Pitre Science College, Devrukh (Autonomous), MS, (415804), India.

3 Department of Chemistry, Anandibai Raorane Arts Commerce and Science College, Vaibhavwadi, University of Mumbai, MS, (416810) India.

4 Shri Yashwantrao Patil Science College, Solankur, Shivaji University Kolhapur, MS, (416212) India.

5 Department of Physics, Dr. Patangrao Kadam Mahavidyalaya, Ramanadnagar (Burli), Shivaji University Kolhapur, MS, (416308) India.

*Author to whom correspondence should be addressed: sikandar.physics@gmail.com (Sikandar H. Tamboli)

ABSTRACT

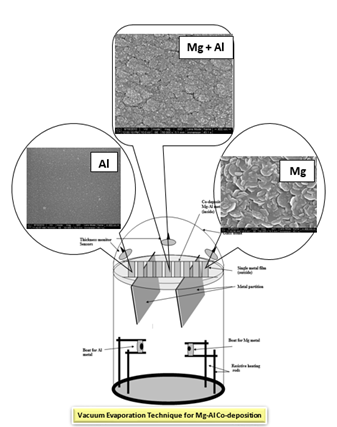

Thin film coatings play a crucial role in various technological applications, including optoelectronics, protective layers, and display technologies. This study investigates the structural, optical, and mechanical properties of MgO-Al₂O₃ co-deposited mixed thin films prepared via steam oxidation of vacuum-evaporated Mg-Al mixed metal thin films. The films, with a controlled thickness of 300 nm, were oxidized at varying temperatures (573 K, 623 K, and 673 K) to analyze their phase composition, surface morphology, optical transmittance, band gap, refractive index, adhesion, and intrinsic stress. X-ray diffraction (XRD) confirmed the formation of a cubic MgO-dominated structure, while Al₂O₃ remained amorphous, indicating a stable mixed oxide formation. Scanning electron microscopy (SEM) revealed a transition from granular and cauliflower-like morphologies in pure Mg and Al films to a well-decorated granular structure in co-deposited films, further evolving into agglomerated grains upon oxidation. Higher oxidation temperatures enhanced optical transmittance (above 450 nm), band gap (2.9–3.4 eV), and refractive index (1.69–1.72), attributed to improved stoichiometry and reduced grain boundary scattering. Mechanical properties, including adhesion (33–39.9 × 10⁴ N/m²) and intrinsic tensile stress (55–80 × 10⁷ N/m²), increased with oxidation temperature due to enhanced crystallinity and interfacial bonding. However, higher temperatures also induced void formation, contributing to intrinsic stress. These findings highlight the tunability of MgO-Al₂O₃ thin films for advanced applications, particularly in plasma display panels (PDPs), where improved durability and optical performance are critical. The study demonstrates that oxidation temperature is a key parameter in optimizing the functional properties of co-deposited oxide thin films.

Significance of the Study:

The work demonstrates tunable multifunctional properties in oxide thin films through oxidation temperature control, addressing critical challenges in protective coatings for optoelectronics. The MgO-Al₂O₃ synergy combines MgO’s optical advantages with Al₂O₃’s environmental stability, particularly beneficial for plasma display panels. The systematic correlation between processing conditions and film characteristics provides a roadmap for optimizing durability-performance trade-offs. These insights advance the design of robust, high-transparency coatings for display technologies and other applications requiring tailored optical-mechanical properties.

Summary of the Study:

This study fabricated MgO-Al₂O₃ mixed thin films via steam oxidation (573–673 K) of co-deposited Mg-Al layers. XRD revealed cubic MgO with amorphous Al₂O₃, while SEM showed temperature-dependent morphological evolution. Higher temperatures enhanced optical transmittance (≥450 nm), bandgap (2.9–3.4 eV), and refractive index (1.69–1.72) through improved crystallinity. Mechanical properties exhibited trade-offs: adhesion increased (33–39.9 × 10⁴ N/m²) but so did tensile stress (55–80 × 10⁷ N/m²) due to grain growth and void formation.