Sharif Saleem, Gul Faroz Ahmad Malik, Amir Farooq, Farooq Ahmad Khanday

Department of Electronics and Instrumentation Technology, University of Kashmir, Hazratbal, Srinagar-190006, Jammu and Kashmir, India.

*Author to whom correspondence should be addressed:

farooqkhanday@kaghmiruniversity.ac.in (F. A. Khanday)

ABSTRACT

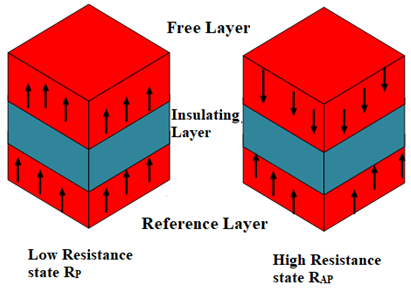

In this paper, the first principle study of tunnel magnetoresistance (TMR) for various oxide materials has been done. More than 30 materials have been taken into consideration and divided into four different categories based on their bandgap. The four categories are 2-4 eV bandgap materials, 4-6 eV bandgap materials, 6-8 eV bandgap materials, and 8-10 eV bandgap materials. The first principle simulations and the device-level simulations of various MTJ configurations were executed using the various oxide materials. The results reveal that maximum TMR ratio is observed in oxide materials having lower bandgap value and it reduces with the increase in oxide material bandgap. The maximum TMR ratio is observed in Cu2O material and minimum TMR is observed in BeO material. The oxide materials with bandgap less than 3ev are the best materials for device level fabrication and they provide 100% TMR for the oxide thickness up to 3 nm.

Significance of the study:

This study systematically investigates tunnel magnetoresistance (TMR) in various oxide materials, providing crucial insights for optimizing magnetic tunnel junction (MTJ) devices. It highlights the impact of bandgap on TMR, demonstrating that materials with lower bandgaps offer superior performance, which is vital for the development of high-efficiency spintronic devices.

Summary of the study:

The paper presents a first-principle study on tunnel magnetoresistance (TMR) across more than 30 oxide materials, categorized by their bandgaps. Results show that materials with lower bandgaps yield higher TMR ratios, with Cu2O achieving the maximum TMR. The study concludes that oxide materials with bandgaps under 3 eV are optimal for device-level fabrication, providing 100% TMR up to 3 nm thickness.